SolidWorks CAM Professional – Integrated CNC Programming for Advanced Manufacturing

Automate and Streamline Your CNC Workflow with SolidWorks CAM

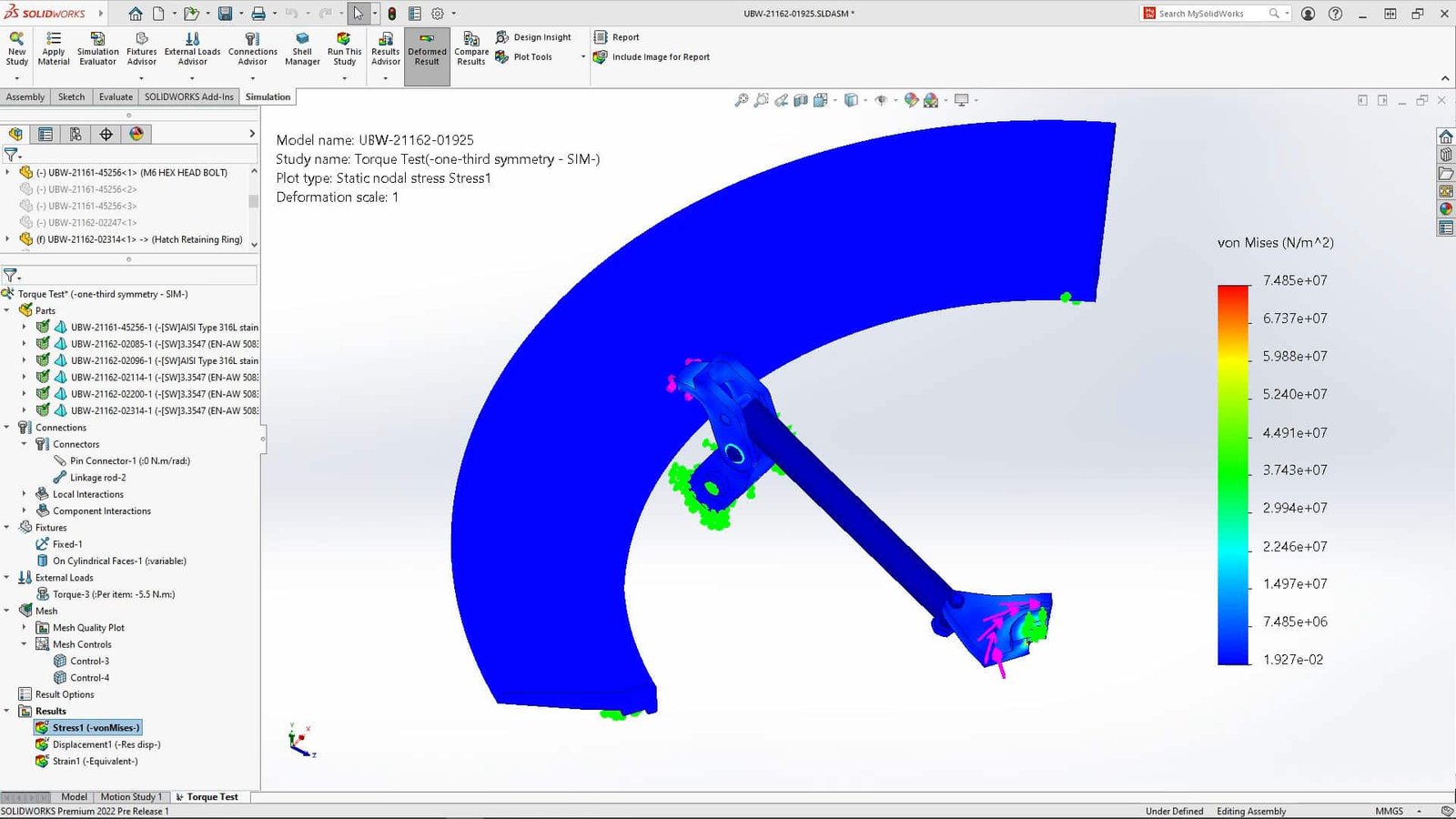

Precision. Speed. Integration. In today’s manufacturing world, engineers and CNC programmers need software that works seamlessly from design to machining. SolidWorks CAM is the advanced computer-aided manufacturing (CAM) solution that delivers intelligent, rule-based machining directly inside the SolidWorks interface.

At GraphicLicense, we provide genuine SolidWorks CAM Professional licenses with secure digital delivery, setup support, and flexible subscription or perpetual options. Whether you’re programming for 3-axis mills, multi-surface operations, or high-volume production parts, SolidWorks CAM helps you save time, reduce errors, and get to market faster.

What Is SolidWorks CAM Professional?

SolidWorks CAM Professional is a fully integrated CAM solution developed by Dassault Systèmes. Built on the industry-trusted SolidWorks 3D CAD platform, it enables users to automate CNC programming directly from SolidWorks part or assembly files. This integration ensures that design changes automatically update toolpaths, minimizing errors and redundant work.

While SolidWorks CAM Standard covers basic 2.5-axis milling and turning operations, SolidWorks CAM Professional adds advanced capabilities such as:

-

Assembly-level machining

-

High-speed machining (HSM)

-

VoluMill™ support for adaptive roughing

-

Turning with live tooling

-

Custom machining strategies

-

Data-driven automation with tolerance-based machining

If your shop needs to handle more complex parts or higher production volumes, SolidWorks CAM Professional gives you the flexibility, control, and speed to scale your manufacturing process.

Why Choose SolidWorks CAM Professional?

Choosing SolidWorks CAM Professional means investing in a tightly integrated CAM system that improves collaboration between design and manufacturing. Here are the key advantages:

Fully Integrated with SolidWorks CAD

No exporting, importing, or file translation needed. Your CAM data lives inside the SolidWorks file, ensuring full associativity with the model.

Advanced Machining Features

Access turning, 3+2 indexing, high-speed roughing, and assembly machining. Program more complex parts with fewer setups and higher efficiency.

Automated and Rule-Based Machining

Use tolerance-based machining to automate toolpath decisions based on design dimensions and tolerances. This reduces manual input and improves consistency across parts.

Feature Recognition Technology

Automatically identify machinable features such as pockets, bosses, holes, and slots. The software applies pre-set strategies for faster toolpath generation.

Custom Technology Databases (TechDB)

Create and reuse company-specific machining standards for tools, materials, and feeds and speeds. Automate operations based on predefined best practices.

Assembly-Level Programming

Program multiple components or setups within a SolidWorks assembly. Useful for multi-part fixtures or simultaneous operations on multiple workpieces.

VoluMill Integration

Get access to VoluMill™ high-performance roughing strategies for faster material removal, longer tool life, and reduced machine wear.

Turning Support with Live Tooling

Program complex lathe operations including OD/ID turning, grooving, threading, and C-axis live milling. Perfect for modern mill-turn machines.

Key Features of SolidWorks CAM Professional

Tolerance-Based Machining

Automatically apply different machining strategies based on the tolerance data embedded in the CAD model. For example, tighter tolerances may trigger additional finishing passes or reduced feed rates.

Feature-Based Recognition (FBR)

SolidWorks CAM Professional recognizes geometric features that are suitable for milling or turning and applies machining operations automatically based on defined rules.

Toolpath Simulation and Verification

Visually verify toolpaths within SolidWorks. Detect collisions, gouges, and over-travel issues before sending code to the machine.

Post-Processor Customization

Use or modify dozens of available post-processors to generate G-code for virtually any CNC machine. You can also create custom posts for specific machines or controllers.

High-Speed Machining (HSM)

Utilize advanced toolpaths that minimize machine wear and increase productivity. Strategies include trochoidal milling and adaptive clearing for roughing and finishing.

3+2 Indexing

Perform indexed machining using rotary tables or multi-axis setups. Ideal for angled holes, side features, and complex prismatic parts.

Turning and Mill-Turn Support

SolidWorks CAM Professional supports lathe programming with live tooling, sub-spindles, and multi-station turrets. Machine complex turned parts in fewer setups.

Assembly Machining

Machine components in an assembled state, helping you validate clearances, tool access, and work offsets in a real production environment.

SolidWorks CAM Standard vs. CAM Professional

| Feature | SolidWorks CAM Standard | SolidWorks CAM Professional |

|---|---|---|

| Part-level programming | ✔ | ✔ |

| Feature-based recognition | ✔ | ✔ |

| Tolerance-based machining | ✔ | ✔ |

| Assembly machining | ✘ | ✔ |

| Turning support | ✘ | ✔ |

| High-speed machining | ✘ | ✔ |

| VoluMill adaptive roughing | ✘ | ✔ |

| 3+2 indexing | ✘ | ✔ |

| TechDB customization | Basic | Advanced |

If you need greater flexibility and support for advanced manufacturing tasks, SolidWorks CAM Professional is the clear choice.

Who Should Use SolidWorks CAM Professional?

SolidWorks CAM Professional is built for manufacturers, machinists, and engineers working in:

-

Precision CNC job shops

-

Aerospace and defense manufacturing

-

Medical device production

-

Automotive and motorsports

-

Industrial equipment and automation

-

Custom tooling and mold shops

-

Education and training institutions

Whether you’re machining single prototypes or large production runs, SolidWorks CAM Professional helps you improve productivity, reduce setup time, and ensure consistent results.

System Requirements

Operating System

Windows 10 or 11 (64-bit)

Processor

3.3 GHz or faster Intel or AMD multi-core processor

Memory (RAM)

16 GB minimum (32 GB recommended for large assemblies)

Graphics

NVIDIA or AMD dedicated GPU with OpenGL support (certified by SolidWorks)

Storage

Solid State Drive (SSD) with at least 20 GB free space

Internet Connection

Required for activation, updates, and access to cloud features

Note: SolidWorks CAM Professional is an add-in that requires a compatible version of SolidWorks (Standard, Professional, or Premium).

Licensing and Delivery

When you purchase SolidWorks CAM Professional from GraphicLicense, you receive:

-

A genuine Dassault Systèmes license

-

Secure digital delivery and activation

-

Access to updates and enhancements during your subscription

-

Perpetual or annual subscription options

-

Business-ready documentation and license compliance

-

Installation guidance and technical support

Network and floating licenses are also available for teams and educational institutions.

Why Buy SolidWorks CAM Professional from GraphicLicense?

Authorized Software Reseller

We offer only verified licenses with full support eligibility, guaranteed authenticity, and professional software services.

Fast Digital Delivery

Your license and activation instructions are delivered via email within hours, so you can begin machining the same day.

Competitive Pricing

We offer flexible pricing, multi-seat discounts, and bundle deals for customers purchasing multiple SolidWorks products.

Expert Support

Our team includes certified SolidWorks professionals who understand both design and machining. Get assistance with installation, setup, and post-processing.

Business-Ready Services

Receive VAT-compliant invoices, quotes, and licensing documentation to satisfy procurement and compliance requirements.

How to Get Started

-

Choose your SolidWorks CAM Professional license on GraphicLicense

-

Complete your secure online checkout

-

Receive your license key and installation instructions by email

-

Install the software and activate your license via the SolidWorks admin portal

-

Begin programming parts with intelligent, rules-based toolpaths—directly inside SolidWorks

Need help with setup or selecting the right configuration? Our support team is ready to guide you.

Conclusion

SolidWorks CAM Professional is the ideal manufacturing companion for SolidWorks users who need more than just basic machining. With support for multi-axis operations, turning, high-speed roughing, and assembly-level programming, it gives you the tools to compete in today’s fast-paced manufacturing environment.

If you’re ready to automate your CNC workflows, improve accuracy, and integrate your design and manufacturing teams, SolidWorks CAM Professional is the solution you’ve been looking for.

Buy your license today from GraphicLicense and take full control of your production pipeline.

There are no reviews yet.